BMW Germany: Pushing the Boundaries of Prototype E-Cars

In a world where German engineering sets the gold standard, you can bet that projects involving BMW require a lot more than just turning a few wrenches. The project I had was a first privilege of working for BMW Germany. Out of somewhere thanks to my efforts on game creation... Let's just say it involved an NDA and a car designed for something beyond closed walls. Using advanced point cloud technology, I helped create a digital model of a car for BMW's internal testing staff. If that doesn't sound like a standard day at the office, that's because it wasn't. My older computer almost crashed with the high resources it needed to even look at the data knowing the deadline was coming soon.

Thanks to this project I quickly invested in a higher grade desktop and software to catch other big projets.

It wasn't just about recreating a car

It was about making sure every detail was as precise as possible, right down to the last inner bolt of the rear mirror. This wasn't for showroom floors or commercials; it was for the kind of testing that turns good cars into great ones. Prototype stuff let's say. I took their point cloud data and worked my magic to create something usable for BMW's research team. Let's just say their test drivers won't be the only ones with data at their fingertips. And as I never had done such a big step forward in 3D work, it still motivates me each day on other massive yet insane projects.

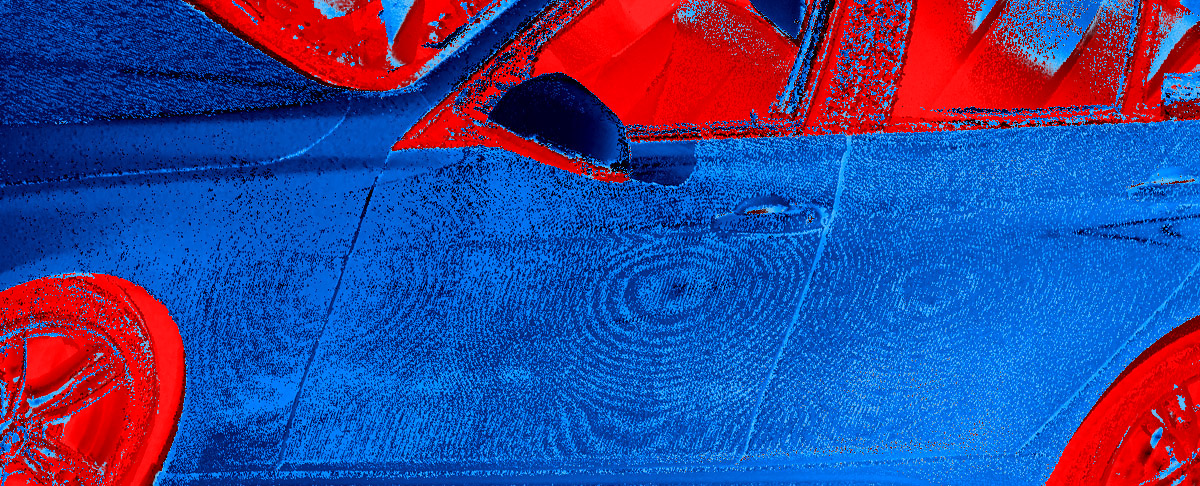

<< Nope, it's not this model. NDA remember? On the other hand a good shot of another work of mine.

When working with BMW,

You quickly learn that the devil is indeed in the details. A millimeter mistake here or there could mean the difference between ultimate driving precision and something less "ultimate." You can imagine that the stakes were pretty high, but that's where I thrive—in a space where technology, accuracy, and passion intersect.

This wasn't about speed—although, being BMW, there was plenty of it—it was about precision and deadline or no money. 2 Months time and delivered a HQ 3D product that ensures their testing was backed by the most realistic and high-resolution on half mm precision model possible. No shortcuts. Only the best, as you'd expect from BMW.

Working under a strict NDA means I can't tell you everything—but I can tell you that the pride of crafting something that lives behind the closed doors of BMW Germany's testing facilities is something else entirely. I mean.. You get me right? 'THE BMW' Company, thank you, come back again!